DITA, PLM Data. Illustrated Parts Catalogues sit at the intersection of engineering data and technical documentation. For many organizations, especially in manufacturing and industrial environments, the data that defines a product already exists in a Product Lifecycle Management (PLM) system. At the same time, the explanations, structure, and usability of that data depend on technical writers.

This creates a familiar challenge: the information exists, but it lives in different systems, in different formats, and for different audiences. Bridging that gap is where modern DITA-based documentation workflows come into play.

The Two-Source Reality Technical Writers Live With:

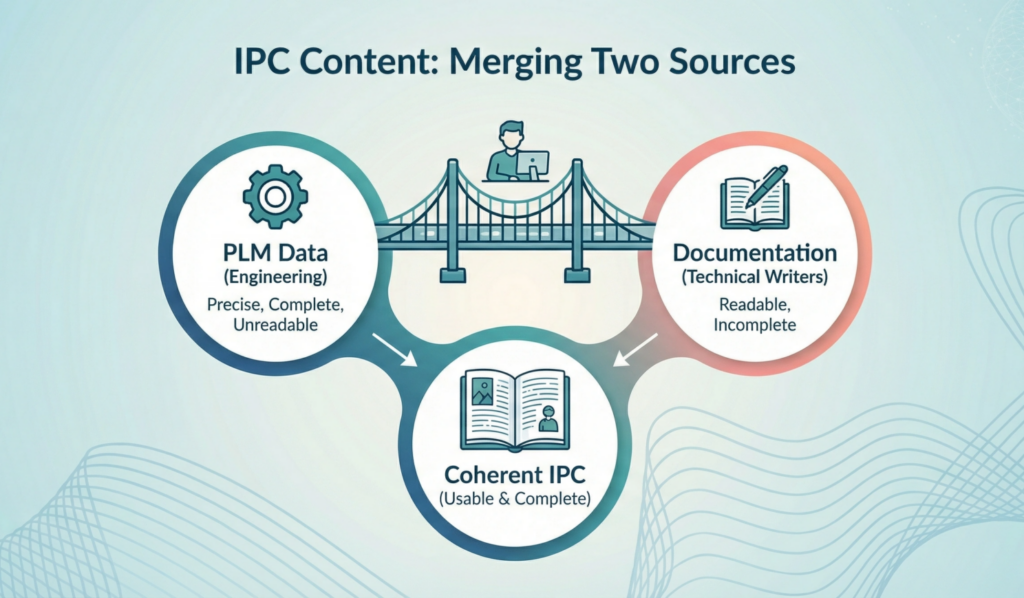

In most organizations, IPC content is built from at least two distinct sources.

One source is the PLM system. Tools such as Windchill or Teamcenter hold authoritative product data such as parts lists, hierarchies, configurations, and relationships. This data is precise and complete, but it is structured for engineering and lifecycle management, not for documentation delivery.

The second source is documentation content created by technical writers. This includes explanations, usage context, illustrations, safety notes, and supporting information that make parts data understandable and usable.

Neither source alone is sufficient. PLM data is accurate but unreadable to end users. Documentation content is readable but incomplete without the underlying product data. The technical writer’s role is to merge these two sources into a single, coherent information set.

Why PLM Data Cannot Simply Be “Dropped” into a CCMS

A common misconception is that a CCMS can simply consume PLM data and publish it as documentation. In practice, this rarely works.

PLM systems store product data in formats optimized for lifecycle control, not structured documentation. When PLM data is passed directly into a CCMS, the system often does not understand the relationships, hierarchy, or intent of the information. The result is content that is technically present but unusable.

This is where transformation matters. PLM data needs to be converted into DITA, given structure, enriched with metadata, and aligned with documentation topics before it can become usable content.

Flipping PLM Data into DITA

One of the most effective ways to bridge PLM and documentation is to transform PLM output into DITA topics. When product data is flipped into DITA, it gains structure that documentation systems can understand.

Assemblies, subassemblies, and parts can become structured topics rather than raw data tables. Metadata can be applied to describe variants, configurations, and applicability. Once in DITA, this content can be managed, reused, filtered, and combined with writer-authored content.

This transformation is not about replacing PLM systems. The PLM remains the system of record. The documentation environment becomes the system that shapes that data into readable, usable documentation.

Mixing PLM Content & Authored Content into One Source

For technical writers, the real challenge is not just importing PLM data, but mixing it with authored content in a controlled and maintainable way.

An Illustrated Parts Catalogue is rarely just a list of parts. It includes explanatory text, illustrations, references to procedures, and sometimes links to external systems. These elements do not belong in the PLM, but they must be tightly connected to PLM-derived data.

A DITA-based approach allows these two content streams to be merged. PLM-derived topics provide the authoritative parts information. Writer-authored DITA topics provide context and explanation. Together, they form a single, readable documentation set that can be customized for different audiences or products.

Custom Documentation from Shared Sources

Once PLM data and authored content are structured in DITA, customization becomes far more achievable.

The same underlying content can be reused to create different IPCs for different product configurations, customers, or markets. Filtering and metadata allow documentation teams to generate tailored outputs without duplicating content.

This is especially important in B2B environments, where documentation is often customized per customer or contract rather than sold as a standard catalog.

Enabling Interactive & Connected IPCs

When PLM-derived content is structured and enriched, it also becomes possible to extend IPCs beyond static documents.

For example, parts entries can be “hot-buttoned” so users can jump from a part illustration to a parts ordering system, a service bulletin, or a related procedure. These connections are not managed in the PLM itself, but in the documentation layer that understands user needs.

By structuring PLM data in DITA and managing it alongside authored content, documentation teams gain control over how information is presented and connected, without altering the source systems.

Why This Matters for Technical Writers

Technical writers are often responsible for making sense of complex product data that lives outside their tools. Understanding how PLM data can be transformed, structured, and merged with authored content is becoming an essential skill.

Rather than manually reworking engineering data, writers can focus on structuring, contextualizing, and customizing content for users. This improves accuracy, reduces duplication, and makes documentation easier to maintain over time.

Final Thoughts

Illustrated Parts Catalogues are no longer static manuals. They are living documentation assets built from multiple systems and designed for multiple audiences.

By transforming PLM data into DITA and merging it with writer-authored content, documentation teams can create IPCs that are accurate, customizable, and usable. This approach respects the role of PLM systems as systems of record while giving technical writers the tools they need to deliver meaningful documentation.

For organizations managing complex products, this bridge between PLM and DITA is not just a technical improvement. It is a documentation strategy that scales.

Want to See XDelivery CDP & XDocs CCMS in Action?

Looking to modernize your documentation process with AI?

Let’s connect. Contact Bluestream to learn how our native integration with oXygen XML Editor/Author can elevate your structured authoring environment. From authoring to review to multichannel publishing, we support the workflows that power your content lifecycle.