WhitePaper

Bluestream & Manufacturing

Written by Andrew Douglas, February 2026

The Problem

Complex machines present unique challenges for organizations from the ‘drawing board’, through manufacture, delivery and ongoing servicing.

Machine longevity presents its own challenges

Whilst not necessarily the first thing that comes to mind, consideration of the authoring platform is very important.

Large equipment, complex machines, and ‘smart’ factories will have a lifespan expectation of many years. Often being in use 20 + years after first commissioning. Ownership of some equipment may well change multiple times, whilst modifications and updates will also likely be made. Just like your car or motorcycle, anything with moving parts needs regular maintenance to keep working at its optimum. Unlike your car or motorcycle there aren’t tens of thousands of trained technicians to look after specialist machines.

Therefore, there is a far greater reliance on the technical manuals/technical content. If the equipment is modified, the documentation needs to be updated to reflect these changes. Therefore, the original content must remain editable.

For over 20 years, XML has been the preferred language for technical documentation and since 2005 DITA has been the preferred standard of XML to use. Using XML separates the content from the formatting, and allows for content to be published in various formats including PDF for print and XHTML/HTML5 for online.

XML authoring is supported by many different editors and will still be accessible in 40 years’ time, the same may not be true of unstructured editing tools.

Complex Machines

& Solutions Are Often Customized

A train manufacturer will offer various options to customers dependent upon their geographic location and their specific needs. This may include breaking systems air conditioning driver auctions and much more.

A company supplying air traffic control equipment will also have many options both for hardware and software. A company supplying wind farms will again have different options for different conditions; onshore or offshore ground conditions, accessibility etc.

Data is stored in different places

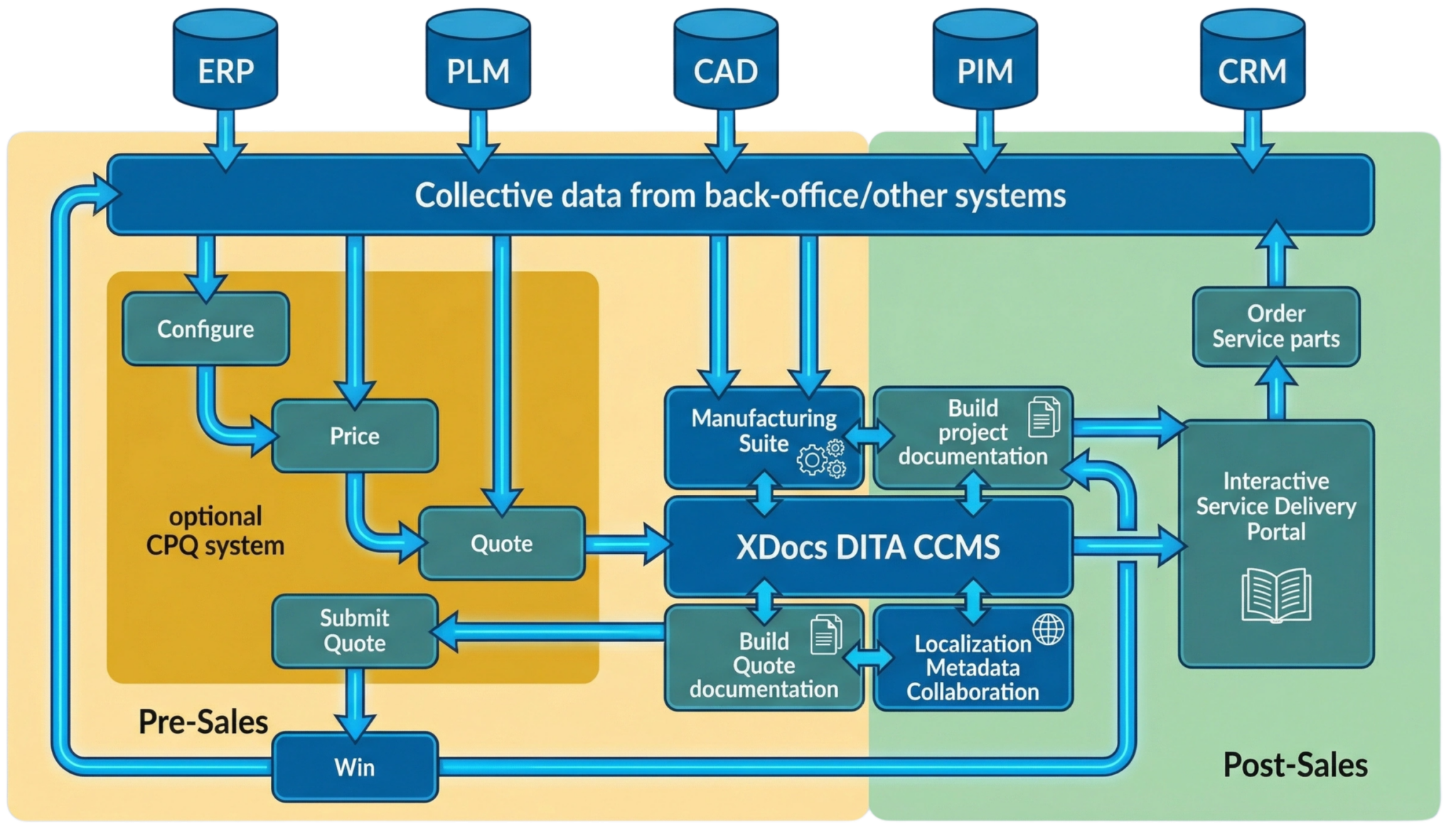

Modern companies use many different systems ERP, PLM, PIM, CAD, CRM and more. All of these systems hold data which is needed by the technical authors for the creation of the various documents that support the equipment. A lot of this data is stored as BOMs (Bills of Materials).

There are lots of different types of BOMs each serving a different purpose:

Manufacturing Bill of Materials (mBOM)

Manufacturing BOMs (mBOM) are employed

when a business needs to show all the parts and assemblies required to build a finished product, parts requiring processing prior to assembly must also be included. They contain information that is sent to all the integrated business systems involved including enterprise resource planning (ERP), materials resource planning (MRP) etc. mBOMs are the most common type of BOM for a manufacturing company.

Engineering Bill of Materials (eBOM)

The engineering BOM (eBOM) is developed during the product design phase and is often based on Computer-Aided Design (CAD) or Electronic Design Automation (EDA) tools.

It lists the items, parts, components, sub-assemblies and assemblies in the product as designed by the engineering team. More than one eBOM can be associated with the finished product.

Service BOM

The Service BOM (developed during the design

phase) typically includes a list of all the parts,

installation steps and repair instructions that service

technicians use when installing, or servicing a product.

Sales BOM

Unlike other types of BOMs, a Sales BOM provides details of a finished product prior to its assembly during the sales phase. In a Sales BOM, both the finished product and the components appear as separate items in the sales order document.

The parent item is listed only as a sales item, rather than as an inventory item, the children are listed as subitems.

Assembly Bill of Materials

An assembly BOM is similar to a Sales BOM in which the parent item is listed as a sales item and not an inventory item.

However, a notable difference is that unlike the Sales BOM, only the finished product appears in the sales document.

Assembly BOMs can be either single-level or multi-level

Production BOM

A Production BOM often serves as the foundation for a production order. It lists the components and subassemblies that comprise a finished product, as well as prices, descriptions, quantities and associated units of measure.

During the production process, physical components can be converted into actual finished products

Single-Level BOM

A single-level BOM is typically used for products whose constructions are not complex and do not include sub-assemblies. Typically, this document contains a total count of all the parts used in the construction of a product and those parts are listed in part number order. The structure of this type of document only allows for one level of children in components, assemblies and material.

Multi-Level BOM

Multi-level BOMs are used for more complex

constructions and include sub-assemblies, (which may include further levels of sub-assemblies). Each item number (either a raw material or labor) must associate with a parent item, except at the top-most level.

With information stored in so many places it is easy for mistakes to creep in which can have very serious consequences.

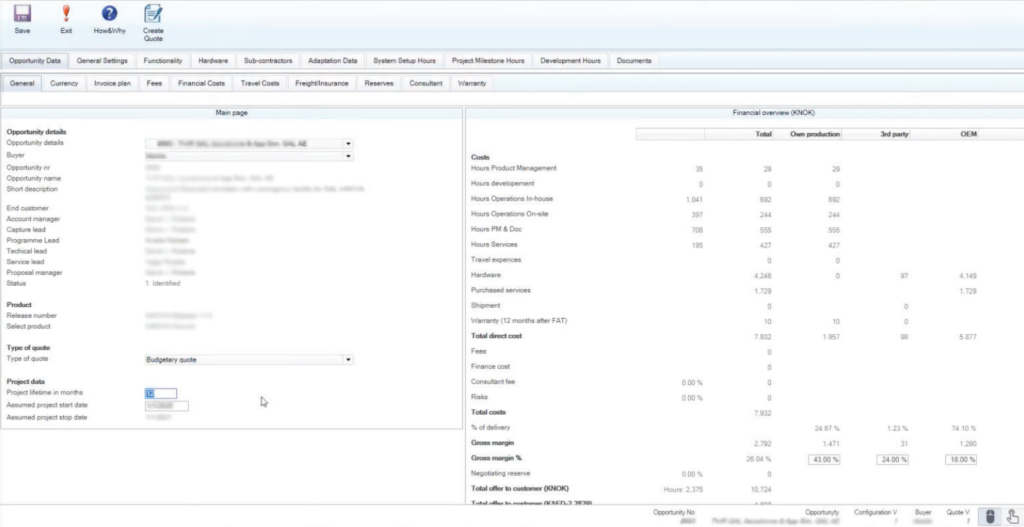

Presales – it starts with a quote

Whist not the first stage of the sales-cycle, at some point there will be the need to produce a quotation. This may involve using a (CPQ) configure price quote system, these tools can connect to ERP and CRM systems and utilize selection screens to build the pricing.

Once the quotation has been accepted BOMs (bill of materials) are often used to support in the manufacturing stage.

Production BOM

With complex solutions, technical documentation often needs to be supplied alongside the quotation. Once built and delivered there are more documentation requirements. This may be in print format via PDF or more likely delivered electronically. It may include installation guides, user guides, maintenance schedules, troubleshooting information, IPCs (illustrated parts catalogues), IETMs (interactive electronic technical manuals) and more.

These guide may also need to be delivered in multiple languages.

XML and DITA are ideally suited to all of this.

Problems in the field

Engineers in the field often only have access to bulky, out-of-date printed manuals.

These don’t show machine specific modifications and make it hard to identify replacement parts.

Bluestream XDocs Manufacturing Suite

The manufacturing suite has been developed to support companies delivering complex equipment and solutions including machines, hardware and software.

The Quote Stage

By using XML and DITA, standard ‘boilerplate content’ can be easily created and reused across quotations. This might include product descriptions, functionality matrixes and much more. This content is much easier to curate within a CCMS and can also be easily localized. XDocs DITA CCMS can be incorporated with CPQ systems and generate information to support the quotations automatically based on a particular configuration. It can then publish this information in the required format PDF or online.

The Delivery Stage

XDocs Manufacturing Suite has connectors that enable it to connect to the other systems deployed by companies including ERP and PLM making the information available to the technical authors. This reduces the chance of errors and speeds the writing process. It has also been developed to support all types of BOM, which can be imported and managed within the system. Documentation can also be automatically generated from these BOMs.

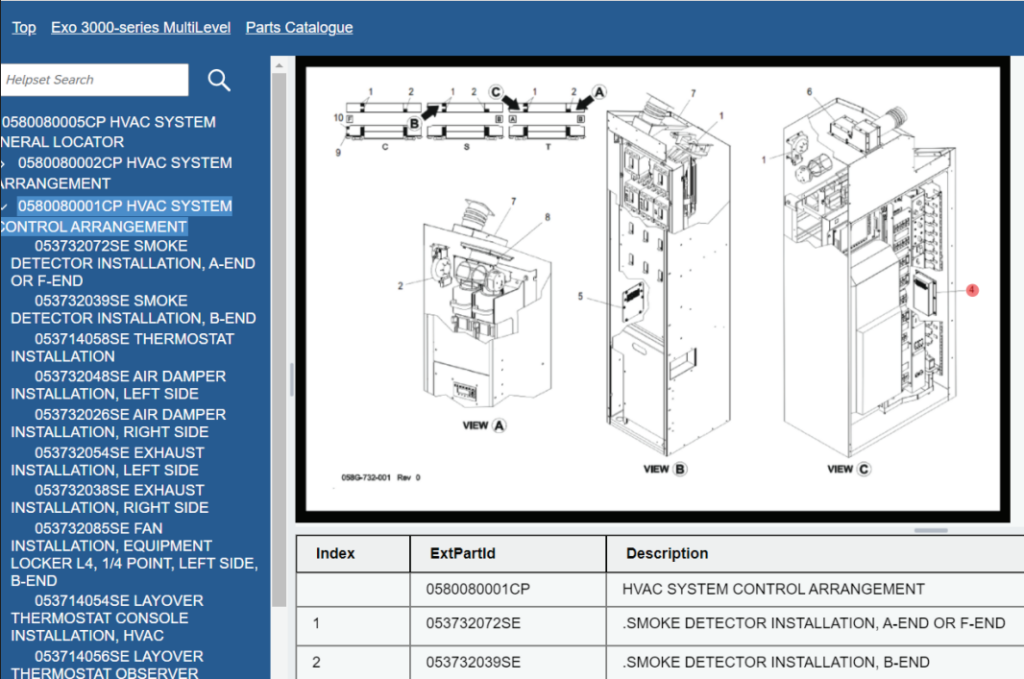

IPCs (Illustrated Parts Catalogues)

IPCs allow engineers to easily identify a particular component utilizing General Assembly, Sub-Assembly and exploded component drawings. XDocs Manufacturing Suite supports the creation of illustrated parts catalogues, authors can import CAD drawings and diagrams then, use the built in hot-spotting tool to link parts numbers. It also supports browser based review of all content prior to approved publishing. SMEs (Subject Matter Experts) can be easily incorporated into review cycles using XDocs WEX – a simple to use browser based review and collaboration application. When delivered electronically an IPC can be easily linked to a fulfilment system. This enables engineers in the field to instantly request replacement parts directly from the manufacturer. IPCs reduce the chance of the wrong part being ordered and create a valuable revenue stream.

Interactive Service Documentation Portal

Bluestream have developed their own delivery platform that links directly to the core XDocs database. Customers can use this platform to create interactive service delivery portals where all technical documentation can made available to customers and engineers according to permissions.

Maintenance Manual Parts Catalog Training Maintenance Schedule

Benefits of the Combined Solution

With XDocs Manufacturing Suite you control the flow of ‘Service Information’ from Engineering to Fulfilment:

- Create better documentation faster, reuse content with confidence and update information with ease.

- A streamlined workflow for producing integrated service documentation.

- Build IPCs, Maintenance Schedules, Installation Guides etc. and localize them to any language

- Rapid information updates (to all output formats i.e. IPC, Doc, Maintenance Schedules.

- Full control of the information flow:

– Audit trail (what was changed, when’ by who)

– Instant comparison between versions.

- Helps ensure data consistency and integrity.

- Eliminates system redundancy.

- Build fully customizable Web-based Delivery Portals

See XDocs + PLM in action

If the challenges and opportunities outlined in this whitepaper resonate with your organization, Bluestream is here to help.

Whether you are looking to streamline technical documentation, improve content reuse, or better manage complex manufacturing information, our team has the expertise to support you. Get in touch with us to discuss your specific needs, explore tailored solutions, and learn how Bluestream can help you increase efficiency, reduce complexity, and future-proof your documentation strategy.