Across the automotive industry, documentation teams are under increasing pressure to manage more content, more variants, and more delivery channels than ever before.

As vehicle platforms grow in complexity and product lifecycles accelerate, many organizations are re-evaluating how their technical documentation is authored and maintained.

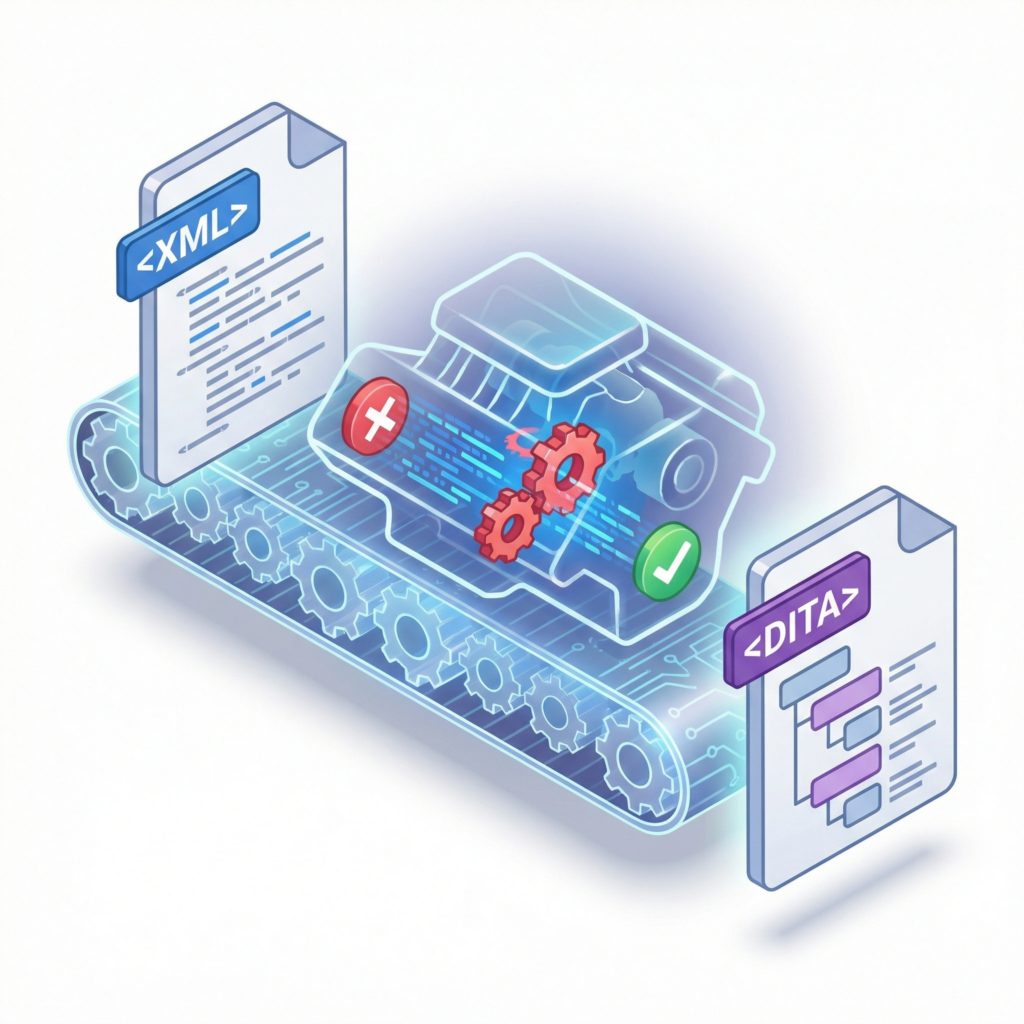

One trend becoming increasingly clear is the shift from custom or legacy XML implementations to DITA. For automotive documentation teams, this move is less about adopting a new standard and more about gaining structure, scalability, and long-term sustainability.

The Legacy XML Reality in Automotive Documentation

Many automotive organizations adopted XML years ago to gain more control over documentation than traditional word-processing tools allowed. These XML models were often custom-built to reflect specific products, internal processes, or historical requirements.

While these approaches provided flexibility early on, they also introduced long-term challenges. Custom XML structures can be difficult to maintain, hard to extend, and heavily dependent on internal expertise. Over time, even small changes require significant effort, and onboarding new writers becomes increasingly difficult.

As documentation volumes grow, these limitations become more visible.

Growing Complexity Drives the Need for Change

Modern automotive documentation must support a wide range of outputs and audiences. Service manuals, repair procedures, owner documentation, training materials, and digital help systems all rely on the same underlying information.

At the same time, automotive products are increasingly modular and configurable. Variants, markets, regulations, and model years multiply the number of documentation permutations that teams must support.

Legacy XML systems struggle to scale under these conditions. Reuse becomes difficult to manage, and duplication increases the risk of inconsistency. This is often the tipping point that leads teams to explore DITA.

Why DITA Aligns Well with Automotive Needs

DITA was designed to manage complex technical information at scale. Its topic-based architecture, specialization capabilities, and reuse model make it particularly well suited to automotive documentation.

By breaking content into modular topics, automotive teams can reuse procedures, warnings, and reference information across multiple vehicle platforms. Conditional processing and metadata allow teams to tailor content for specific models, regions, or regulatory requirements without duplicating content.

DITA also provides a standardized framework that reduces reliance on custom XML structures and internal tooling.

Standardization Without Losing Flexibility

One concern automotive organizations often raise is whether moving to DITA limits flexibility. In practice, many find the opposite to be true.

DITA offers a well-defined core structure while still allowing specialization where necessary. This balance allows teams to standardize authoring practices while accommodating industry-specific needs such as parts documentation, safety information, and regulatory content.

Standardization also makes it easier to integrate tools, workflows, and vendors across global teams.

Improving Collaboration and Maintainability

As documentation teams grow and become more distributed, collaboration becomes critical. DITA-based workflows are widely supported by modern CCMS platforms, which provide version control, reuse tracking, and governance features.

This reduces the burden on individual writers to manage complex dependencies manually. Updates can be made once and reflected everywhere they apply, improving both efficiency and accuracy.

For automotive organizations managing documentation across multiple regions and suppliers, this maintainability is a significant advantage.

Preparing Automotive Documentation for Digital Delivery

Automotive documentation is increasingly delivered digitally rather than as static manuals. Technicians, dealers, and customers expect searchable, interactive documentation accessible across devices.

DITA supports this shift by separating content from presentation. The same source content can be published to web portals, PDFs, embedded systems, and mobile experiences without reauthoring.

Teams moving from legacy XML often find that DITA better supports modern delivery expectations and future digital initiatives.

A Strategic Move, Not Just a Technical One

For automotive organizations, the move from XML to DITA is rarely just a technology upgrade. It reflects a broader shift toward sustainable documentation practices that can keep pace with product complexity and change.

By adopting DITA, teams reduce technical debt, improve reuse, and position documentation as a strategic asset rather than a maintenance burden.

Final Thoughts

The automotive industry continues to evolve rapidly, and documentation must evolve with it. While legacy XML systems played an important role in the past, many automotive documentation teams are finding that they no longer meet today’s demands.

DITA provides a proven, scalable framework that supports reuse, consistency, and digital delivery. For organizations facing growing complexity and long-term maintenance challenges, the move from XML to DITA represents a practical step toward future-ready documentation.

Explore our breakdown of the top 10 ways structured content prepares your docs for AI…

Want to See Metadata Strategies in Action?

Looking to modernize your documentation process with AI?

Let’s connect. Contact Bluestream to learn how our native integration with oXygen XML Editor/Author can elevate your structured authoring environment. From authoring to review to multichannel publishing, we support the workflows that power your content lifecycle.

FAQ: Advanced Metadata, Structured Authoring, and AI

Why are automotive companies moving from XML to DITA?

Many automotive organizations originally implemented custom XML models to improve structure and control. Over time, these custom implementations can become difficult to maintain, extend, and scale. DITA offers a standardized, topic-based framework that supports reuse, scalability, and long-term sustainability without relying on highly customized structures.

Isn’t DITA just another form of XML?

Yes, DITA is built on XML. However, it is not simply a format. DITA provides a standardized architecture with defined topic types, reuse mechanisms, and metadata support. This structure reduces the need for custom schema development and makes documentation more maintainable across teams and tools.

How does DITA help manage vehicle variants and model years?

DITA supports conditional processing and metadata tagging, which allows documentation teams to tailor content for specific vehicle models, configurations, markets, or regulatory requirements. Instead of duplicating content, teams can maintain a single source and apply filters to generate variant-specific outputs.

Will moving to DITA disrupt existing workflows?

Transitioning to DITA does require planning, particularly around content modeling and migration. However, many automotive organizations find that structured authoring and modern CCMS workflows ultimately streamline collaboration, version control, and updates. With the right planning, disruption can be minimized and long-term efficiency improved.

Can DITA support service manuals and Illustrated Parts Catalogues?

Yes. DITA’s modular structure works well for service procedures, diagnostics, warnings, and parts documentation. When combined with metadata and structured delivery platforms, DITA enables dynamic navigation, filtering, and reuse across service manuals and IPC content.

What is the biggest advantage of moving to DITA?

For many automotive teams, the biggest advantage is maintainability. Updates can be made once and reused across multiple outputs. Standardization reduces technical debt, improves onboarding for new writers, and positions documentation for digital and future-ready delivery.

Is DITA only suitable for large automotive organizations?

DITA is particularly valuable for organizations managing large documentation sets, multiple variants, and frequent product updates. However, even mid-sized automotive documentation teams benefit from its structure and reuse capabilities when content complexity begins to grow.